What is a Chocolate Packaging Machine and How Does It Work

In the ever-evolving chocolate industry, the efficiency and effectiveness of packaging are crucial to maintaining product integrity and consumer appeal. A chocolate packaging machine plays a vital role in this sector, automating the process of packing chocolate products to ensure speed, precision, and protection from external factors that may affect quality.

According to a recent market research report by MarketsandMarkets, the global chocolate packaging market is projected to grow from USD 6.6 billion in 2020 to USD 9.2 billion by 2025, highlighting the increasing demand for innovative packaging solutions. These machines not only streamline the packaging process but also adapt to various shapes and sizes of chocolate products, enhancing operational efficiency.

Understanding how a chocolate packaging machine operates is essential for manufacturers seeking to optimize their production lines and meet consumer expectations in a competitive landscape.

Understanding Chocolate Packaging Machines: Definition and Functionality

Chocolate packaging machines play a crucial role in the chocolate production process, ensuring that products are sealed and preserved correctly. These machines utilize heat sealing mechanisms to create airtight packages that maintain freshness and quality. Understanding the factors that contribute to seal integrity is essential, as inadequate sealing can lead to contamination and spoilage. The review of heat sealing in flexible food packaging highlights various environmental and material factors that affect seal performance, emphasizing the importance of high-quality packaging for chocolate products.

When developing chocolate products, especially for small and medium enterprises, incorporating effective packaging solutions is vital. Quality Function Deployment (QFD) can help identify customer needs and translate them into product specifications, making chocolate more competitive in the domestic market. Additionally, advancements in technology, including machine learning, can further enhance packaging processes by optimizing design and production efficiency.

Tips: Always choose packaging materials that are specifically designed for chocolate to ensure optimal protection against moisture and temperature fluctuations. Regularly maintain and calibrate packaging machines to ensure consistent seal quality. Finally, consider consumer preferences in packaging aesthetics to enhance market appeal.

Key Components of Chocolate Packaging Machines Explained

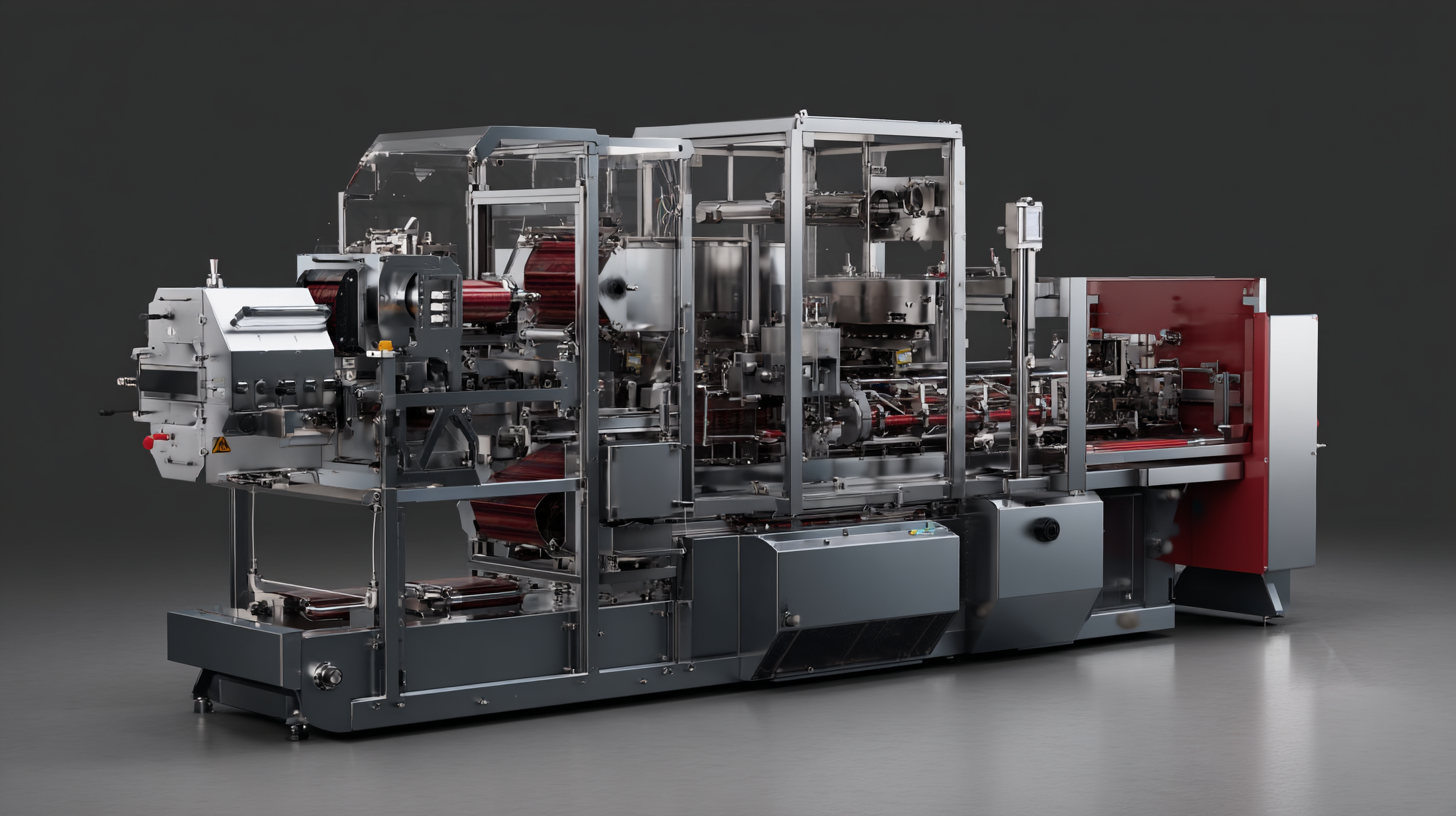

Chocolate packaging machines play a crucial role in the confectionery industry, ensuring that products are presented appealingly while maintaining freshness and quality. Key components of these machines include the feeding system, which manages the flow of chocolate into the packaging unit, and the sealing mechanism, which secures the packages tightly to prevent contamination. Additionally, the wrapping system is essential for providing the final presentation, whether through flow wrapping, which envelopes the chocolate, or other methods tailored to specific product shapes and sizes.

Another vital element in modern chocolate packaging is automation. Advanced technologies are integrated into machinery, allowing for increased efficiency and consistency in production processes. Recent advancements showcase sophisticated systems designed to handle aerated and enrobed chocolates, reflecting a growing industry trend towards versatility and high performance. With innovations such as modular and hybrid machines, manufacturers can enhance productivity and meet evolving consumer demands for both product quality and sustainability.

Chocolate Packaging Machine Efficiency Comparison

The Working Mechanism of Chocolate Packaging Machines: Step by Step

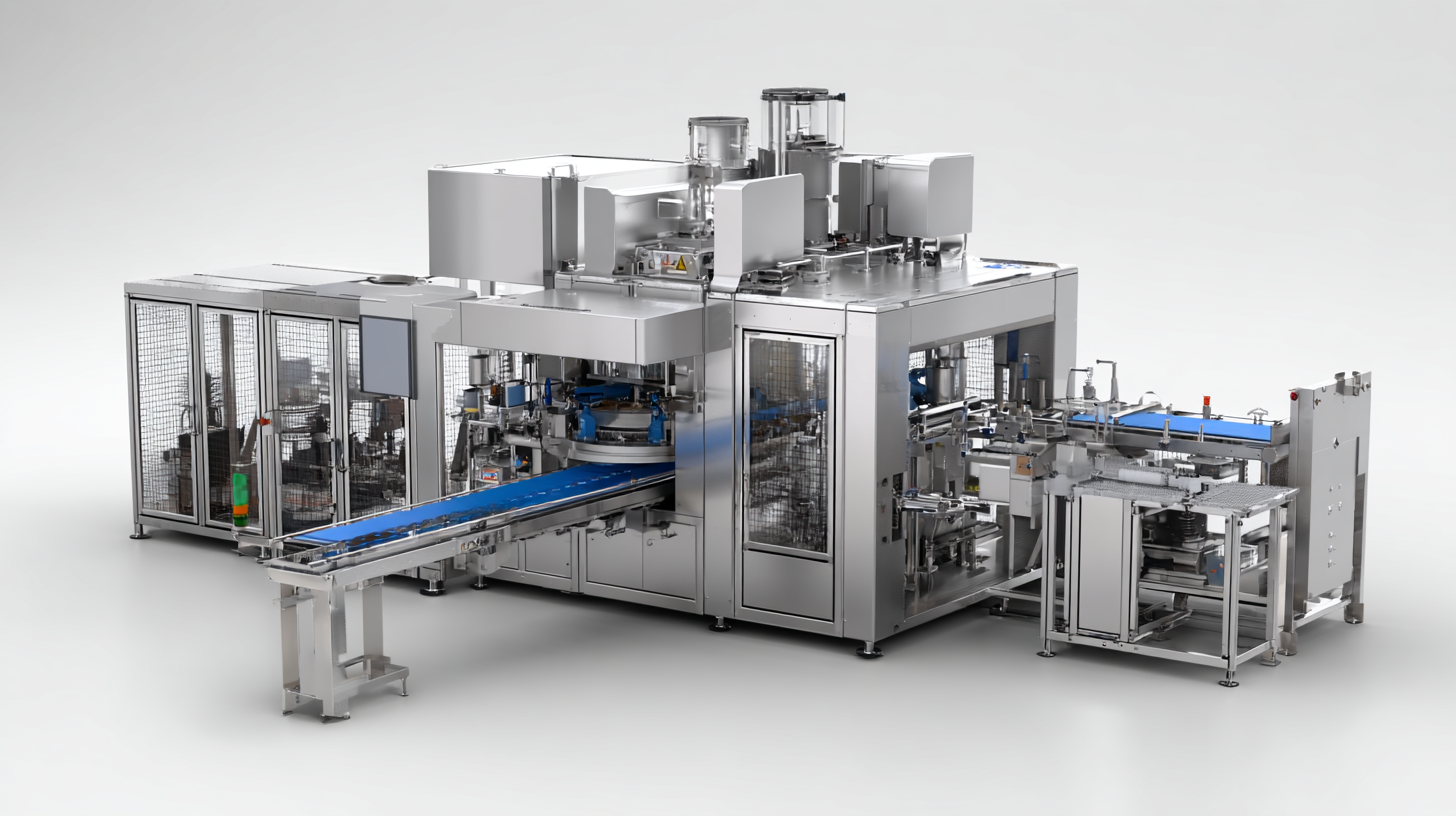

Chocolate packaging machines play a crucial role in ensuring that products remain fresh and appealing. The working mechanism of these machines typically involves several key steps that enhance efficiency and maintain quality. Firstly, the process starts with the feeding of chocolate bars or products into the machine, where they are aligned correctly for packaging. Next, a specialized formation system shapes the packaging material to fit the product dimensions precisely.

Following formation, various sealing mechanisms, such as heat sealing, are employed to ensure that the packages are securely closed, preventing contamination and loss of freshness. Recent advancements in technology, like the “Snap-then-Squeeze” packaging mechanism, improve the ease of opening while maintaining seal integrity. Additionally, automated systems, such as robotic pick-and-place technologies, enhance the efficiency of collating products into cartons, minimizing human error and optimizing production timelines. An understanding of these mechanisms is essential for chocolate manufacturers to deliver high-quality products to consumers.

Chocolate Packaging Machine Specifications

| Feature | Description | Value |

|---|---|---|

| Machine Type | Horizontal Flow Wrapper | Standard |

| Production Speed | Output per minute | 300 - 700 pcs |

| Packaging Material | Film types suitable for chocolate | BOPP, PET, Aluminum Foil |

| Dimensions | Machine Size | 4m x 1m x 2m |

| Power Supply | Electricity Requirement | 220V, 50Hz |

| Control System | User Interface | Touchscreen Control |

| Safety Features | Integrated safety systems | Emergency Stop, Safety Guards |

| Maintenance | Recommended Frequency | Monthly |

Advantages of Automated Chocolate Packaging Systems

Automated chocolate packaging systems offer numerous advantages that significantly enhance production efficiency and product quality. According to a report by Research and Markets, the global chocolate packaging market is projected to grow at a CAGR of 4.6% from 2021 to 2026, driven largely by advancements in automation. These systems are designed to streamline the packaging process, reducing manual labor and minimizing errors. They can operate at higher speeds, allowing manufacturers to package more products per hour, which is essential in meeting the rising consumer demand for chocolate products.

Automated chocolate packaging systems offer numerous advantages that significantly enhance production efficiency and product quality. According to a report by Research and Markets, the global chocolate packaging market is projected to grow at a CAGR of 4.6% from 2021 to 2026, driven largely by advancements in automation. These systems are designed to streamline the packaging process, reducing manual labor and minimizing errors. They can operate at higher speeds, allowing manufacturers to package more products per hour, which is essential in meeting the rising consumer demand for chocolate products.

Another significant benefit of automated systems is the consistency they provide. With precise control over packaging parameters such as size, weight, and sealing, these machines ensure that every package is uniform, which enhances brand reputation and customer satisfaction. A study by Freedonia Group highlighted that over 75% of chocolate manufacturers have adopted automation in their packaging processes. This adoption not only improves operational efficiency but also reduces material waste, which can lead to significant cost savings over time. As demands for sustainable practices grow, automated packaging systems that optimize material usage are becoming increasingly important in the chocolate industry.

Choosing the Right Chocolate Packaging Machine for Your Needs

Choosing the right chocolate packaging machine is crucial for manufacturers aiming to maintain product quality and aesthetic appeal. Different types of chocolate products, such as bars, truffles, or bulk items, require specific packaging solutions. Considerations include the machine's capacity, speed, and the type of packaging materials compatible with the equipment. For instance, if you're looking to package chocolate bars, a flow pack machine may be ideal for providing a tight seal and showcasing the product effectively.

Additionally, evaluating the ease of operation and maintenance of the packaging machine is equally important. A user-friendly interface can reduce training time for staff and enhance productivity. It's also essential to assess the machine's flexibility in accommodating various package sizes and types, ensuring it can adapt to market demands. Ultimately, investing in a suitable chocolate packaging machine not only streamlines the packaging process but also contributes to preserving the quality and freshness of the chocolate, enhancing the overall customer experience.

Related Posts

-

Challenges in Chocolate Bar Wrapping Machine Efficiency: Insights from Industry Data

-

How to Choose the Right Cocoa Machines for Your Business Needs

-

Overcoming Common Challenges in Hot Cocoa Maker Production: Insights and Solutions

-

Exploring the Alternatives to Traditional Hot Chocolate Machines for Your Beverage Business

-

How to Choose the Best Hot Chocolate Maker Machine for Your Home

-

How to Choose the Best Chocolate Warmer Machine for Your Business Needs